FAQ: frequently asked questions

Your burning questions, our honest answers. Let’s go!

General

All our products are Made in Germany – from development and production to assembly. Around 60% of the components are manufactured in-house, while the rest comes from regional suppliers that meet the same high-quality standards as we do at H+B Hightech GmbH. Only a few components are sourced elsewhere in Europe. By relying on regional Industry 4.0-level suppliers, we ensure quality, sustainability, and short supply chains.

The NINE hub gear is a fully enclosed system, sealed against environmental influences. This makes it maintenance-free and highly resistant to wear, with durability designed for several thousand kilometers. Its nine gears are perfectly graduated, ensuring fast and precise shifting. With a gear range of 554%, the NINE hub gear offers the widest range compared to other hub gears, providing enough flexibility for both steep climbs and fast descents. In addition, it is designed for an input torque of up to 250 Nm, making it capable of handling the demands of powerful motors and heavy loads with ease. Unlike oil-lubricated hub gears, the NINE operates with permanent grease lubrication, eliminating the need for regular oil changes.

VPL Vapor Propulsion Labs is the contact for the American region. Contact VPL here.

Retrofitting the 3X3 NINE is possible under certain conditions. This requires consultation and inspection by a 3X3-certified dealer. Please note:

-

Retrofitting with the mechanical shifting system is straightforward.

-

The dealer will first check whether the frame is suitable for retrofitting.

-

The 3X3 NINE offers different options for torque support. The dealer will select the appropriate solution for the specific bike.

-

Retrofitting the E-Shift is only possible in combination with the BOSCH Smart System and requires prior coordination and approval by the bicycle manufacturer.

Our products are designed for a very long service life and maximum durability. Our suppliers meet the same high-quality standards that we apply ourselves at H+B Hightech GmbH. We also prioritize short supply chains, preferably working with regional suppliers. Our own production is designed to be as sustainable as possible, for example through one of the largest solar panel installations in the Stuttgart area, covering 10,000 m², as well as heat recovery from our machining processes.

On our website you can find a list of all dealers and distributors under: https://www.3×3.bike/en/dealer/

The noise in the freewheel is completely normal. Inside the hub, several clutches work together, but in freewheel mode mainly one of them takes over the function.

Due to the interaction of forces, a second clutch may briefly make contact.

This is technically intended and can sound slightly different depending on speed and gear.

The overall sound results from the freewheel principle. Just like with a ratchet freewheel (e.g. DT Swiss), springs press the toothed discs together while pedaling. In freewheel mode, the discs (clutches) slide over each other, creating the characteristic clicking sound.

Gear shifting

Yes, that is an advantage of gear hubs over derailleur systems. They can be shifted even when standing still and also multiple gears at once. As an example: If you are cut with a fully loaded cargo bike and thus forced to decelerate heavily, it is very difficult to get into a lower starting gear with a derailleur system. In addition to endangering road traffic through lurching starts, this is also bad for the material and further increases wear.

Yes, shifting several gears at once or even shifting while standing still are no problem with the 3X3 NINE gear hub.

Thanks to its compatibility with all common thru-axles and quick-release systems, the NINE can be integrated into almost any bicycle. With high efficiency and a gear range of 554%, it is suitable for both touring bikes and mountain bikes. The input torque of up to 250 Nm makes the hub particularly well-suited for e-bikes and cargo bikes with powerful motors. Its long service life combined with maintenance-free operation also makes the NINE attractive for frequent everyday riders who do not want to regularly take care of their bike’s technology.

The NINE hub gear is approved exclusively for installation in the rear wheel. Other installation types must be reviewed and approved in advance by H+B Hightech GmbH. Use is permitted for bicycles that, in accordance with §1 paragraph 3 StVG, are not classified as motor vehicles and that comply with generally applicable safety standards.

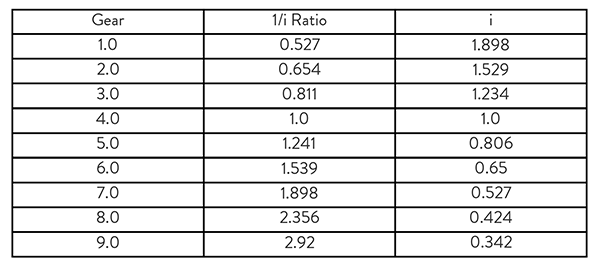

554,35%

An automatic function is not available at this time.

Due to the shifting logic with two cables, this is currently not technically or economically feasible and is therefore not planned in the near future.

Service & Maintenance

The 3X3 NINE is protected against moisture ingress according to the latest standards. However, you should not clean the bicycle with a high-pressure washer. Aggressive cleaning agents can also damage the hub. Use qualified bicycle cleaners and follow the application instructions provided. Pay special attention to the disc brake: contamination, including cleaning agents, can significantly impair braking performance.

For end customers: Complaints are handled through the retailer. Please contact the dealer from whom you purchased the product.

For retailers: In the event of a warranty claim, please use the complaint form at the following link to report the case: https://www.3×3.bike/warranty/

No, otherwise the warranty will be voided.

The statutory warranty in Germany is 2 years.

The 3X3 NINE hub gear is protected against dirt and water by a special sealing concept and, thanks to grease lubrication, does not require oil changes. Nevertheless, you should regularly clean the gearbox and drivetrain. The necessary maintenance intervals depend on usage time and weather conditions. In addition, regularly check all bolts (except the gearbox housing screws) and the shift cables. Once a year, you should take your bicycle to a specialist dealer for a full service to ensure that all safety-relevant components such as the frame and brakes are checked for wear.

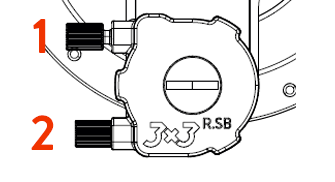

A little play in the twist shifter is necessary for proper function. If there is too much play, you can reduce it by evenly tightening both adjustment screws.

If shifting into a lower gear is delayed: readjust the shift cable at the upper adjustment screw (1).

If shifting into a higher gear is delayed: readjust the shift cable at the lower adjustment screw (2).

These include the sprocket, chain, chainring, belt, belt pulley, tensioner pulleys, shift cables, grip rubber, and brake discs. Have the drivetrain of your bicycle checked regularly by a specialist workshop.

Currently, brake discs from the manufacturers Fahrwerker, Magura, and Tektro are available.

Please contact your Dealer: https://www.3×3.bike/en/dealer/

Check the following points:

- Is the distance between the frame and the nut at least 2 mm?

- Was the nut tightened with 40 Nm torque?

- Is the seal carrier properly seated in the cover behind the sprocket

In the gear shifts from 3 → 4 and 6 → 7, a change of planetary stages takes place. Because additional parts are moved in the process, the shifting force is slightly higher. This is normal and does not represent a fault.

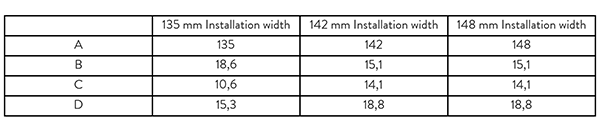

Yes, there is a spoke adapter. It is available for 135 mm quick release as well as 142 / 148 mm thru-axle.

With the adapter, you can lace and true the wheel without first having to install the shifting mechanism, the actuator, or the axle plate. In addition, the gear hub can be held in place when replacing the adapter.

CAUTION: The spoke adapter must not be used to loosen or tighten the sprocket.

If abnormal freewheel noises occur, proceed as follows:

-

First perform a calibration ride (see the Auto Calibration tutorial).

-

Check whether the M38 nut is tightened to 40 Nm and the chain sprocket is securely mounted on the drive.

-

If there is no improvement, submit a warranty claim including the purchase invoice, the serial number on the housing, and a detailed error description. Use our complaint form on the website at the following link: https://www.3×3.bike/en/warranty/

Calibration of the 3X3 E-Shift actuator is always necessary whenever the actuator and hub have been separated, for example when replacing the brake disc. In addition, calibration can be helpful if shifting performance deteriorates. The calibration procedure can be found in the 3X3 User Manual and in our video tutorials.

The 3X3 trigger is equipped with a CR2032 button cell. Depending on the frequency of shifting and connection with the service tool, the battery life is approximately 0.5–1 year. When the battery voltage drops, the trigger signals this by illuminating the LED with every shift and displaying a warning message on the BOSCH display. Replace the battery promptly to ensure proper functioning of the 3X3 NINE E-Shift. Re-pairing of the trigger and actuator is not required.

If the trigger no longer functions, you can shift manually using the 3X3 Service Tool. The procedure is described in our video tutorials and in the 3X3 User Manual.

The service tool can be accessed via the URL service.3X3.bike. The requirements are as follows:

-

A Bluetooth-enabled device (iOS systems are not supported on mobile devices)

-

Internet connection (once the service tool has been loaded, it also works offline, but the latest software will not be searched for automatically)

-

Google Chrome or Microsoft Edge internet browser

-

A switched-on and functional e-bike with activated HPP and the correct Bosch E-Shift software.

If your 3X3 NINE is still within the 2-year warranty period, contact a certified 3X3 service partner (https://www.3×3./dealer/).

Yes, with the 3X3 E.TR CMD.

It shifts like a conventional thumb shifter from the MTB sector.

es, you can access our service tool at service.3X3.bike (not compatible with iOS devices). Requirements:

-

A Bluetooth-enabled device (iOS systems are not supported on mobile devices)

-

Internet connection (once the service tool has been loaded, it also works offline, but the latest software will not be searched for automatically)

-

Google Chrome or Microsoft Edge internet browser

-

A switched-on and functional e-bike with activated HPP and the correct Bosch E-Shift software.

For this, the latest software must be installed on the actuator using the service tool. Afterwards, the new triggers must be enabled for the actuator.

Technology

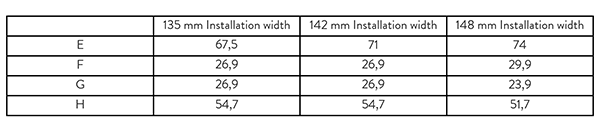

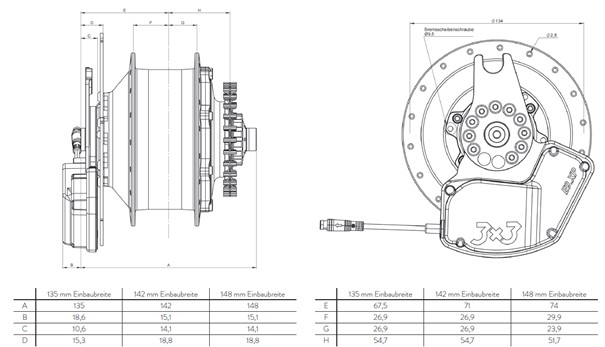

Number of spokes: 32- or 36-hole

Spoke flange distance left:

135mm: 27mm

142mm: 27mm

148mm: 30mm

Spoke flange distance right:

135mm: 27mm

142mm: 27mm

148mm: 24mm

Spoke flange diameter: 134mm (left and right)

Spoke hole diameter: 2.8mm

Spoke flange width: centre of spoke hole 4mm

Maximum spoke tension: 1500N

Preferred spoke pattern:

20″”: 1-cross

24″”-29″”: 2-cross

Recommended spokes: Sapim Strong ED 2.34-2.0 in combination with Sapim Poly-Achs Secure nipples

This should be considered on a case-by-case basis depending on the application. Please feel free to contact us by e-mail info@3×3.bike

No, the 3X3 NINE gear hub is not compatible with a coaster brake.

The maximum permissible system weight of the gear hub is 250 kg. This includes the weight of the rider, clothing, luggage, and – if approved – a trailer including its contents. Testing was carried out in accordance with DIN 79010:2020-02 and Zedler Institute Advanced Plus 2022-11.

No, the electric shifting can currently only be used with a Bosch Smart System. The power supply for the shifting unit and the gear indicator is provided by the e-bike system. Further solutions are already in the works.

Yes, the gear hub is compatible with 142 and 148 mm thru axles with 12 mm bore. This makes the rear ends of the bike significantly stiffer than with quick-release versions.

The individual gears of the 3X3 NINE cannot be changed. By adjusting the primary gear ratio (front sprocket and rear sprocket), the entire gear ratio can be shifted to fast and slow. For e-bikes, observe the specifications for component replacement in order to comply with the legal requirements!

Yes, as long as the bicycle frame is suitable for a belt drive. Please refer to the technical manuals of the company Gates Carbon Drives.

The electronic shifting system can currently only be used in combination with an e-bike system. The power supply for the shifting unit as well as the gear display are provided by the e-bike system.

A chain tensioner is required when there is no other way to properly tension the chain. Without a chain tensioner, the chain may otherwise skip over the sprockets or come off the chainring.

Fahrwerker: 180 mm, 200 mm, 203 mm – 2.0 mm

Magura: 180 mm, 203 mm – 2.0 mm thickness, incl. ABS tonewheel

Tektro: 180 mm, 203 mm – 1.8 mm and 2.3 mm

The 3X3 NINE is only available as a spoke hub and comes with either 32 or 36 spoke holes.

For the 3X3 NINE, Sapim Strong ED spokes with a diameter of 2.34 mm to 2.0 mm are recommended. For optimal results, Polyax Super Secure nipples should be used.

The 3X3 NINE is approved for wheels from 20″ to 29″. For 20″ wheels, the maximum spoke crossing is limited to 1.

iₚᵣᵢₘₐᵣ =

(((weight on crank in kg * 9.81) * (crank length in mm / 1000)) + motor torque in Nm) / 250 Nm

The maximum input load on the gearbox is 250 Nm. If you need more torque at the rear wheel—for example with heavy loads—this can be achieved via the secondary gear ratio.